There is a lot of machinery that goes into operating a commercial kitchen, but your industrial refrigerator is among the most important parts. The efficiency and safety of food production depend on its optimal condition. Maintaining the condenser coils includes cleaning them. If you own a commercial refrigerator, you may clean the condenser coils following this simple approach.

Why Clean the Condenser Coils?

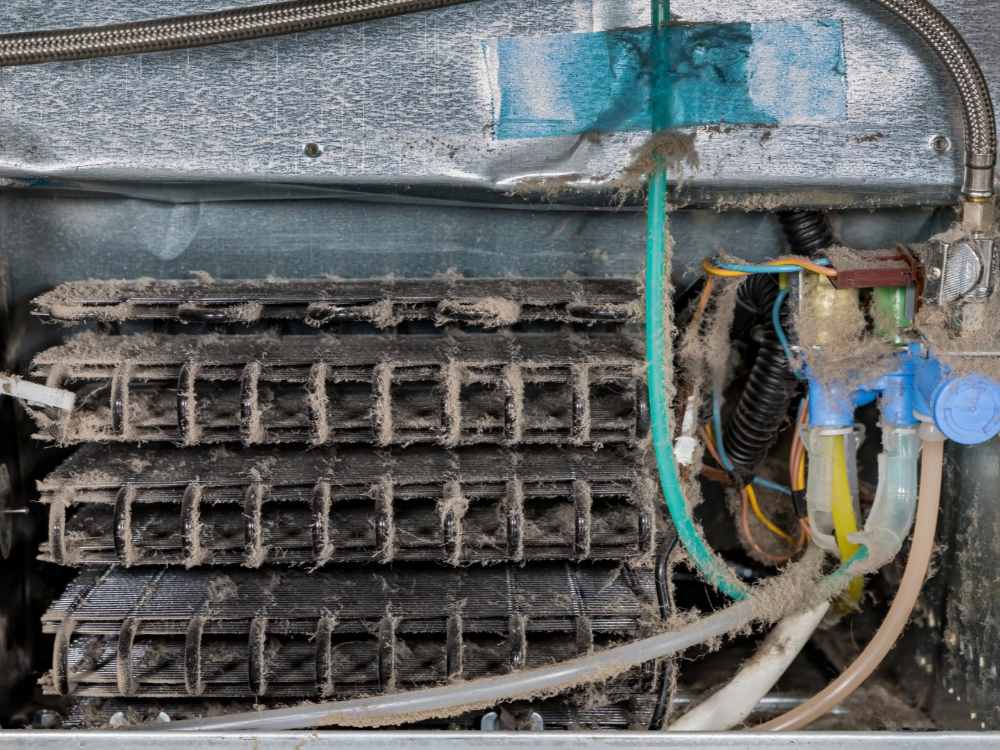

Your commercial refrigerator’s cooling process would not be possible without the condenser coils. These coils help the refrigerator maintain a cool temperature by dissipating excess heat. If dirt and dust accumulate on the coils of your industrial refrigerator, it will have to work harder and less efficiently as time goes on. Increased energy costs or even equipment breakdown may result from this. Maintaining optimal performance and longevity can be achieved by regular cleaning.

Tools You’ll Need

Before you get started, gather the following tools:

- Vacuum cleaner with a brush attachment

- Coil brush

- Fin comb

- Gloves and safety glasses

- Screwdriver

Safety First

Safety should always come first. Turn off and unplug the commercial refrigerator before starting any cleaning. This prevents any electrical accidents and ensures your safety while working on the unit.

Step-by-Step Cleaning Process

1. Locate the Condenser Coils

First, find the condenser coils. They’re typically located at the back or underneath the commercial refrigerator. Refer to your refrigerator’s manual if you’re unsure where to look.

2. Remove Protective Grills

Use a screwdriver to remove any protective grills or panels covering the coils. Set the screws aside in a safe place so you can easily reassemble everything later.

3. Vacuum the Coils

Start by using a vacuum cleaner with a brush attachment to remove loose dust and debris from the coils. Be gentle to avoid damaging the delicate fins.

4. Brush Away Stubborn Dirt

Next, use a coil brush to clean the coils more thoroughly. A coil brush is designed to reach into the spaces between the fins, removing more stubborn dirt and grime. “The brush gets in there where a vacuum can’t,” explains a commercial kitchen expert.

5. Straighten Bent Fins

Bent fins can restrict airflow and reduce efficiency. Use a fin comb to straighten any bent fins carefully. This step helps maintain proper airflow through the condenser coils.

6. Clean the Surrounding Area

Don’t forget to clean the area around the coils. Dust and debris can accumulate around the base of the refrigerator, so give it a good clean to prevent it from being sucked back onto the coils.

7. Reassemble and Restart

Once everything is clean, reattach the protective grills or panels. Plug the refrigerator back in and turn it on. Check to ensure it’s running smoothly and efficiently.

Tips for Regular Maintenance

- Schedule regular cleanings: Make it a habit to clean the condenser coils every three months.

- Monitor performance: Keep an eye on your commercial refrigerator’s performance. If you notice it’s not cooling properly, it might be time to clean the coils.

- Professional service: Consider professional maintenance annually to ensure all parts are in good working order.

Conclusion

If you want your commercial refrigerator to keep working efficiently and last as long as possible, you need to clean the condenser coils. Saving money on energy costs and avoiding expensive repairs is possible with this easy maintenance task. If you want your commercial kitchen to run like clockwork, follow these measures.

FAQs

1. How often should I clean the condenser coils?

Clean the condenser coils every three months for optimal performance.

2. What happens if I don’t clean the coils?

Neglecting to clean the coils can lead to higher energy bills, reduced efficiency, and potential equipment failure.

3. Can I use any vacuum cleaner to clean the coils?

Use a vacuum cleaner with a brush attachment to avoid damaging the coils.

4. What if the coils are hard to reach?

A coil brush can help reach into tight spaces and remove stubborn dirt.

5. Is professional maintenance necessary?

Yes, annual professional maintenance is recommended to ensure all parts are in good working order.